What are the popular capacitor discharge product models?

Popular Capacitor Discharge Product Models

I. Introduction

Capacitor discharge products play a crucial role in various electronic applications, from automotive systems to medical devices. These products utilize the principles of capacitor functionality to store and release electrical energy efficiently. Understanding the significance of capacitor discharge is essential for professionals in electronics, engineering, and related fields. This article will explore popular capacitor discharge product models, their specifications, applications, and future trends in technology.

II. Understanding Capacitor Discharge

A. Basic Principles of Capacitor Discharge

1. **Capacitor Functionality**: A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, the capacitor charges, accumulating energy. Upon discharging, this stored energy is released, providing a quick burst of power.

2. **Discharge Process**: The discharge process involves the rapid release of stored energy, which can be harnessed for various applications. The rate of discharge is influenced by the capacitor's capacitance value and the resistance in the circuit. Understanding this process is vital for designing effective capacitor discharge products.

B. Applications of Capacitor Discharge

1. **Electronics**: Capacitor discharge is widely used in electronic circuits for timing applications, signal processing, and energy storage. It helps stabilize voltage levels and smooth out fluctuations in power supply.

2. **Automotive**: In automotive systems, capacitor discharge products are essential for powering components like airbags, ignition systems, and electronic control units. They provide the necessary energy for quick responses in critical situations.

3. **Industrial Equipment**: Capacitor discharge is utilized in various industrial applications, including welding, motor starting, and power factor correction. These products enhance efficiency and reliability in industrial operations.

4. **Medical Devices**: In the medical field, capacitor discharge products are used in defibrillators and other life-saving equipment. They ensure that energy is delivered swiftly and effectively when needed.

III. Key Features of Capacitor Discharge Products

When evaluating capacitor discharge products, several key features should be considered:

A. Voltage Ratings

The voltage rating indicates the maximum voltage the capacitor can handle without failure. Selecting a product with an appropriate voltage rating is crucial for safety and performance.

B. Capacitance Values

Capacitance values determine how much energy a capacitor can store. Higher capacitance allows for more energy storage, which can be beneficial in applications requiring significant power bursts.

C. Discharge Time

The discharge time refers to how quickly a capacitor can release its stored energy. Faster discharge times are often required in applications like automotive systems and medical devices.

D. Safety Features

Safety features, such as over-voltage protection and short-circuit prevention, are essential in capacitor discharge products to prevent accidents and equipment damage.

E. Size and Form Factor

The physical size and form factor of a capacitor discharge product can impact its usability in various applications. Compact designs are often preferred in portable devices, while larger units may be suitable for industrial equipment.

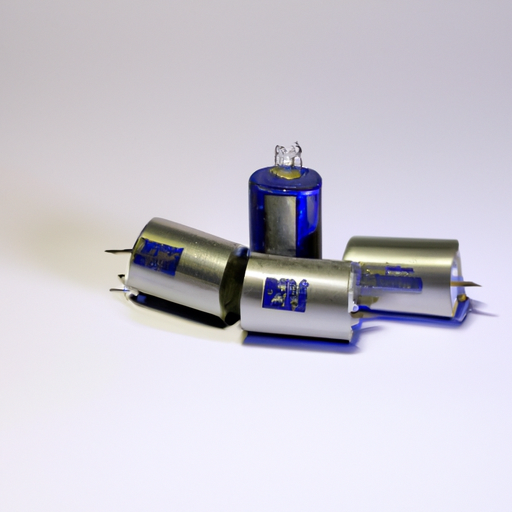

IV. Popular Capacitor Discharge Product Models

A. Model 1: XYZ Capacitor Discharge Unit

1. **Specifications**: The XYZ Capacitor Discharge Unit features a voltage rating of 400V and a capacitance value of 1000µF. It has a discharge time of 0.5 seconds.

2. **Applications**: This model is commonly used in automotive applications, particularly for airbag systems and ignition circuits.

3. **Advantages and Limitations**: The XYZ unit is known for its reliability and quick discharge time. However, its larger size may limit its use in compact electronic devices.

B. Model 2: ABC Capacitor Discharge Tool

1. **Specifications**: The ABC Capacitor Discharge Tool has a voltage rating of 250V and a capacitance of 470µF, with a discharge time of 0.3 seconds.

2. **Applications**: This tool is ideal for electronics repair and testing, allowing technicians to safely discharge capacitors in various devices.

3. **Advantages and Limitations**: The compact design and ease of use make the ABC tool popular among technicians. However, its lower voltage rating may not be suitable for high-power applications.

C. Model 3: DEF Capacitor Discharge Tester

1. **Specifications**: The DEF Capacitor Discharge Tester features a voltage rating of 600V and a capacitance value of 220µF, with a discharge time of 0.2 seconds.

2. **Applications**: This tester is widely used in laboratories and educational settings for testing and demonstrating capacitor discharge principles.

3. **Advantages and Limitations**: The DEF tester is praised for its accuracy and safety features. However, it may be more expensive than other models, limiting its accessibility for some users.

D. Model 4: GHI Capacitor Discharge Circuit

1. **Specifications**: The GHI Capacitor Discharge Circuit has a voltage rating of 500V and a capacitance of 100µF, with a discharge time of 1 second.

2. **Applications**: This circuit is often used in industrial applications for motor starting and power factor correction.

3. **Advantages and Limitations**: The GHI circuit is robust and effective for industrial use. However, its slower discharge time may not be suitable for applications requiring rapid energy release.

E. Model 5: JKL Capacitor Discharge Module

1. **Specifications**: The JKL Capacitor Discharge Module features a voltage rating of 300V and a capacitance of 1500µF, with a discharge time of 0.4 seconds.

2. **Applications**: This module is versatile and can be used in both consumer electronics and industrial applications.

3. **Advantages and Limitations**: The JKL module offers a good balance of performance and size. However, its moderate voltage rating may limit its use in high-power applications.

V. Comparison of Popular Models

A. Performance Metrics

When comparing the performance of these models, factors such as voltage rating, capacitance, and discharge time are critical. The DEF Capacitor Discharge Tester stands out for its high voltage rating, while the ABC Capacitor Discharge Tool excels in compactness.

B. Cost Analysis

Cost is a significant consideration when selecting a capacitor discharge product. The ABC tool is generally more affordable, making it accessible for hobbyists and technicians, while the DEF tester may be more suitable for professional environments due to its higher price point.

C. User Reviews and Feedback

User reviews often highlight the reliability and ease of use of these products. The XYZ Capacitor Discharge Unit receives praise for its performance in automotive applications, while the JKL module is noted for its versatility.

D. Best Use Cases for Each Model

Each model has its strengths and ideal use cases. The XYZ unit is best for automotive applications, the ABC tool for electronics repair, the DEF tester for educational purposes, the GHI circuit for industrial use, and the JKL module for general applications.

VI. Future Trends in Capacitor Discharge Technology

A. Innovations in Capacitor Design

The future of capacitor discharge technology is likely to see innovations in materials and design, leading to more efficient and compact products. Advances in nanotechnology and new dielectric materials may enhance performance.

B. Emerging Applications

As technology evolves, new applications for capacitor discharge products are emerging, particularly in renewable energy systems and electric vehicles. These sectors require efficient energy storage and quick discharge capabilities.

C. Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on creating eco-friendly capacitor discharge products. This includes using sustainable materials and designing products for recyclability.

VII. Conclusion

In summary, capacitor discharge products are essential components in various applications, from electronics to automotive systems. Understanding the specifications, advantages, and limitations of popular models is crucial for selecting the right product for specific needs. As technology continues to advance, the future of capacitor discharge products looks promising, with innovations that will enhance performance and sustainability.

VIII. References

A comprehensive list of references, including academic journals, industry reports, manufacturer specifications, and online resources, can provide further insights into capacitor discharge technology and its applications.