What are the differences between mainstream starting capacitor models?

What are the Differences Between Mainstream Starting Capacitor Models?

I. Introduction

Starting capacitors are essential components in electric motors, playing a crucial role in initiating their operation. These capacitors provide the necessary boost of electrical energy to help the motor start, ensuring it can overcome inertia and begin turning. Understanding the differences between various starting capacitor models is vital for anyone involved in motor maintenance, repair, or selection. This article aims to explore the various types of starting capacitors, their specifications, and how to choose the right one for your needs.

II. Understanding Starting Capacitors

A. Function of Starting Capacitors in Electric Motors

Starting capacitors serve a specific purpose in electric motors: they provide the initial torque required to start the motor. When an electric motor is powered on, it needs a significant amount of torque to overcome the inertia of the stationary rotor. The starting capacitor temporarily stores electrical energy and releases it quickly, creating a phase shift in the motor's windings. This phase shift generates a rotating magnetic field, which helps the motor start.

B. Types of Starting Capacitors

There are three primary types of starting capacitors used in electric motors:

1. **Permanent Split Capacitor (PSC)**: This type of capacitor remains in the circuit during the motor's operation, providing continuous assistance. PSC motors are known for their efficiency and are commonly used in applications where the motor runs for extended periods.

2. **Capacitor Start, Induction Run (CSIR)**: CSIR motors use a starting capacitor only during the initial startup phase. Once the motor reaches a certain speed, a centrifugal switch disconnects the capacitor from the circuit. This type is often used in applications requiring high starting torque.

3. **Capacitor Start, Capacitor Run (CSCR)**: Similar to CSIR motors, CSCR motors use a starting capacitor for initial torque. However, they also include a run capacitor that remains in the circuit during operation, enhancing efficiency and performance.

III. Key Differences Among Mainstream Starting Capacitor Models

A. Construction and Materials

The construction and materials used in starting capacitors can significantly affect their performance and longevity.

1. **Dielectric Materials**: Starting capacitors are made from various dielectric materials, such as polyester and polypropylene. Polypropylene capacitors are generally preferred for their superior thermal stability and lower losses, making them ideal for high-performance applications.

2. **Physical Size and Shape Variations**: Capacitors come in different sizes and shapes, which can influence their installation and compatibility with specific motor designs. Smaller capacitors may be easier to fit into tight spaces, while larger ones may offer higher capacitance values.

B. Electrical Specifications

Electrical specifications are critical when comparing starting capacitors:

1. **Capacitance Values (µF)**: The capacitance value indicates how much electrical energy the capacitor can store. Different motors require different capacitance values for optimal performance, so it's essential to choose a capacitor that matches the motor's specifications.

2. **Voltage Ratings (AC/DC)**: Starting capacitors are rated for specific voltage levels. It's crucial to select a capacitor with a voltage rating that exceeds the motor's operating voltage to prevent failure.

3. **Tolerance Levels**: Tolerance levels indicate how much the actual capacitance can vary from the stated value. A lower tolerance level means more precise performance, which can be critical in applications requiring exact specifications.

C. Performance Characteristics

The performance characteristics of starting capacitors can vary widely:

1. **Starting Torque Capabilities**: Different capacitor models provide varying levels of starting torque. Motors requiring high starting torque, such as those used in heavy machinery, may benefit from capacitors designed for that purpose.

2. **Efficiency Ratings**: Efficiency ratings indicate how effectively a capacitor can convert electrical energy into mechanical energy. Higher efficiency ratings can lead to lower energy costs and improved motor performance.

3. **Temperature Ratings and Thermal Stability**: Capacitors are rated for specific temperature ranges. Choosing a capacitor with a suitable temperature rating is essential for ensuring reliable operation in various environmental conditions.

D. Application Suitability

The suitability of a starting capacitor for a specific application is another critical consideration:

1. **Residential vs. Industrial Applications**: Residential applications may require different capacitor specifications than industrial ones. For example, a capacitor used in a home air conditioning unit may not be suitable for a large industrial compressor.

2. **Compatibility with Different Motor Types**: Not all starting capacitors are compatible with every motor type. It's essential to ensure that the chosen capacitor matches the motor's design and operational requirements.

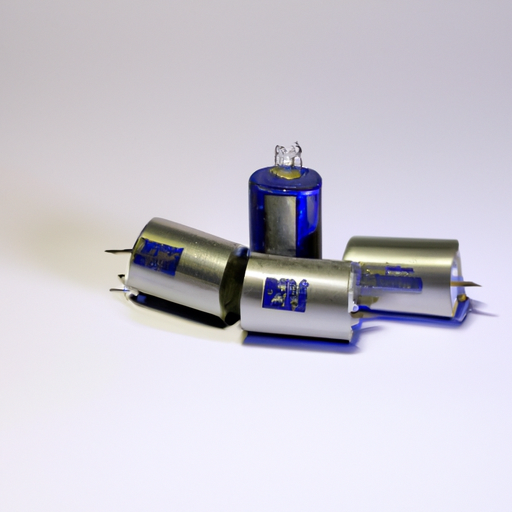

IV. Popular Starting Capacitor Models

A. Overview of Leading Brands and Models

Several brands dominate the starting capacitor market, each offering unique features and specifications:

1. **Brand A**: Known for its high-quality polypropylene capacitors, Brand A offers models with excellent thermal stability and efficiency ratings. Their capacitors are widely used in both residential and industrial applications.

2. **Brand B**: This brand specializes in affordable starting capacitors with a focus on residential applications. Their models are known for their reliability and ease of installation.

3. **Brand C**: Brand C offers a range of high-performance capacitors designed for industrial use. Their products are built to withstand harsh conditions and provide high starting torque.

B. Comparative Analysis of Performance and Reliability

When comparing these brands, it's essential to consider factors such as performance, reliability, and customer reviews. Brand A may excel in efficiency, while Brand B could be more cost-effective for residential users. Brand C's industrial-grade capacitors may be the best choice for heavy-duty applications.

V. Installation and Maintenance Considerations

A. Proper Installation Techniques

Installing a starting capacitor requires careful attention to detail. Always ensure that the power is disconnected before installation. Follow the manufacturer's instructions for wiring and placement, and use appropriate tools to secure the capacitor in place.

B. Maintenance Tips for Longevity

To extend the life of a starting capacitor, consider the following maintenance tips:

- Regularly inspect the capacitor for signs of wear or damage.

- Keep the surrounding area clean and free of debris.

- Ensure proper ventilation to prevent overheating.

C. Signs of Failure and Replacement Indicators

Common signs of capacitor failure include:

- Unusual noises from the motor

- Difficulty starting the motor

- Overheating or burning smells

If you notice any of these symptoms, it's crucial to replace the capacitor promptly to avoid further damage to the motor.

VI. Cost Considerations

A. Price Range of Different Models

Starting capacitors vary in price based on brand, specifications, and performance characteristics. Basic models may cost as little as $10, while high-performance industrial capacitors can exceed $100.

B. Factors Influencing Cost

Several factors influence the cost of starting capacitors, including:

- Brand reputation

- Material quality

- Electrical specifications

C. Cost-Benefit Analysis of Investing in Higher-Quality Models

While higher-quality models may come with a higher price tag, they often provide better performance, efficiency, and longevity. Investing in a reliable starting capacitor can lead to lower maintenance costs and improved motor performance over time.

VII. Conclusion

Choosing the right starting capacitor is crucial for ensuring the efficient operation of electric motors. Understanding the differences between various models, their specifications, and their suitability for specific applications can help you make informed decisions. Whether you're a homeowner, a technician, or an industrial operator, selecting the appropriate starting capacitor can enhance performance and reliability. Always consult with professionals for specific applications to ensure optimal results.

VIII. References

- Manufacturer specifications and datasheets

- Industry publications on electric motor technology

- Online forums and communities for motor repair and maintenance

By understanding the nuances of starting capacitors, you can ensure that your electric motors operate efficiently and effectively, ultimately leading to better performance and longevity.