What are the important product categories for measuring inductors?

Important Product Categories for Measuring Inductors

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various applications, including filtering, energy storage, and signal processing. Measuring inductors accurately is essential for ensuring the performance and reliability of electronic circuits. This blog post will explore the important product categories for measuring inductors, including the types of inductors, measurement techniques, and key product categories.

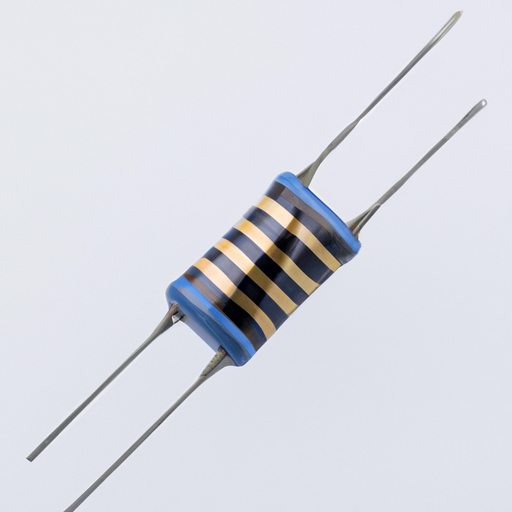

II. Types of Inductors

Understanding the different types of inductors is fundamental to measuring them effectively. Here are the primary categories:

A. Air Core Inductors

Air core inductors are made without a magnetic core, relying solely on the air surrounding the coil to create inductance. They are often used in high-frequency applications due to their low losses and high Q factor.

B. Iron Core Inductors

Iron core inductors use an iron core to increase inductance. They are commonly found in power applications where higher inductance values are required. However, they can suffer from core losses at high frequencies.

C. Ferrite Core Inductors

Ferrite core inductors utilize ferrite materials, which provide high magnetic permeability and low losses at high frequencies. They are widely used in RF applications and power supplies.

D. Toroidal Inductors

Toroidal inductors are wound on a toroidal (doughnut-shaped) core, which minimizes electromagnetic interference and enhances efficiency. They are popular in audio applications and power supplies.

E. Variable Inductors

Variable inductors allow for adjustable inductance values, making them useful in tuning circuits and applications where flexibility is required.

III. Measurement Techniques

Accurate measurement of inductors requires specific techniques and tools. Here are some common measurement methods:

A. LCR Meters

1. Functionality

LCR meters measure inductance (L), capacitance (C), and resistance (R). They apply an AC signal to the inductor and analyze the response to determine its characteristics.

2. Advantages and Disadvantages

LCR meters are user-friendly and provide quick measurements. However, they may have limitations in terms of frequency range and accuracy compared to more specialized equipment.

B. Impedance Analyzers

1. Functionality

Impedance analyzers measure the impedance of inductors over a wide frequency range, providing detailed information about their behavior in different conditions.

2. Advantages and Disadvantages

These devices offer high accuracy and can analyze complex impedance, but they are typically more expensive and require a deeper understanding of impedance theory.

C. Oscilloscopes

1. Functionality

Oscilloscopes can visualize the voltage and current waveforms in inductors, allowing for the analysis of their dynamic behavior.

2. Advantages and Disadvantages

While oscilloscopes provide valuable insights into transient responses, they may not directly measure inductance and require additional calculations.

D. Network Analyzers

1. Functionality

Network analyzers measure the S-parameters of inductors, providing comprehensive data on their performance in a network context.

2. Advantages and Disadvantages

These analyzers are highly accurate and versatile but can be complex to operate and are often more costly.

IV. Key Product Categories for Measuring Inductors

When selecting tools for measuring inductors, consider the following key product categories:

A. LCR Meters

1. Features to Look For

When choosing an LCR meter, look for features such as a wide frequency range, high accuracy, and the ability to measure various component types.

2. Recommended Models

Some popular models include the Keysight E4980A and the B&K Precision 890B, both known for their reliability and performance.

B. Impedance Analyzers

1. Features to Look For

Key features include a broad frequency range, high resolution, and the ability to perform automated measurements.

2. Recommended Models

The Agilent E4990A and the Tektronix TTR500 series are excellent choices for impedance analysis, offering advanced capabilities for inductor measurement.

C. Oscilloscopes

1. Features to Look For

Look for oscilloscopes with high bandwidth, deep memory, and advanced triggering options to capture transient responses effectively.

2. Recommended Models

The Tektronix MDO3000 and the Keysight InfiniiVision series are well-regarded for their performance in analyzing inductors.

D. Network Analyzers

1. Features to Look For

Choose network analyzers with a wide frequency range, high dynamic range, and the ability to perform S-parameter measurements.

2. Recommended Models

The Keysight PNA series and the Anritsu MS4630 series are top-tier options for network analysis, providing comprehensive measurement capabilities.

E. Multimeters with Inductance Measurement

1. Features to Look For

When selecting a multimeter, ensure it has a dedicated inductance measurement function, along with good accuracy and a user-friendly interface.

2. Recommended Models

The Fluke 87V and the Klein Tools MM600 are popular choices, offering reliable inductance measurement along with other essential multimeter functions.

V. Factors Influencing Measurement Accuracy

Several factors can affect the accuracy of inductor measurements:

A. Calibration

Regular calibration of measurement instruments is crucial to ensure accurate readings. Calibration should be performed according to manufacturer specifications and industry standards.

B. Environmental Conditions

Temperature, humidity, and electromagnetic interference can all impact measurement accuracy. It’s essential to conduct measurements in controlled environments to minimize these effects.

C. Frequency Range

Inductors behave differently at various frequencies. Ensure that the measurement tool can operate within the frequency range relevant to your application for accurate results.

D. Component Quality

The quality of the inductor itself can influence measurement outcomes. High-quality components will yield more consistent and reliable measurements.

VI. Applications of Inductor Measurement

Accurate measurement of inductors is vital in various fields:

A. Electronics Design and Development

Engineers rely on precise inductor measurements during the design phase to ensure that circuits function as intended.

B. Quality Control in Manufacturing

Manufacturers use inductor measurements to verify that components meet specifications and maintain quality standards.

C. Research and Development

In R&D, accurate inductor measurements are essential for developing new technologies and improving existing products.

D. Educational Purposes

In educational settings, measuring inductors helps students understand fundamental concepts in electronics and circuit design.

VII. Conclusion

In summary, measuring inductors accurately is crucial for the performance and reliability of electronic circuits. Understanding the different types of inductors, measurement techniques, and key product categories is essential for selecting the right tools. As technology advances, we can expect to see improvements in measurement accuracy and capabilities, making it easier for engineers and researchers to work with inductors in various applications.

VIII. References

- Academic Journals: IEEE Transactions on Power Electronics, Journal of Electronic Materials

- Industry Standards: IEC 60068, IPC-A-600

- Manufacturer Specifications: Keysight Technologies, Tektronix

- Online Resources and Tutorials: Electronics Tutorials, All About Circuits

By understanding the importance of measuring inductors and the tools available, professionals can ensure their designs and applications are successful and reliable.