What is the mainstream production process of filter capacitors?

What is the Mainstream Production Process of Filter Capacitors?

I. Introduction

Filter capacitors are essential components in electronic circuits, playing a crucial role in smoothing out voltage fluctuations and filtering out unwanted noise. They are widely used in power supplies, audio equipment, and various electronic devices to ensure stable and reliable operation. Understanding the production process of filter capacitors is vital for engineers, manufacturers, and anyone interested in electronics. This blog post will explore the mainstream production process of filter capacitors, from raw materials to quality control and distribution.

II. Types of Filter Capacitors

Filter capacitors come in various types, each with unique characteristics and applications.

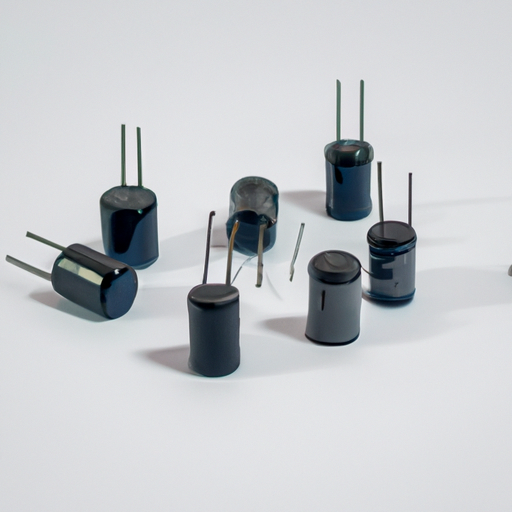

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that offer high capacitance values in a compact size. They are commonly used in power supply circuits due to their ability to handle large voltage fluctuations.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are often used in high-frequency applications and are available in various capacitance values.

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their low loss and high stability, making them suitable for audio and RF applications.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and reliability. They are often used in applications where space is limited, such as in mobile devices.

E. Comparison of Different Types

Each type of filter capacitor has its advantages and disadvantages, making them suitable for specific applications. Understanding these differences is crucial for selecting the right capacitor for a given circuit.

III. Raw Materials

A. Overview of Materials Used in Filter Capacitors

The production of filter capacitors begins with the selection of raw materials, which significantly influence the performance and reliability of the final product.

1. Dielectric Materials

Dielectric materials are crucial for capacitor function, as they store electrical energy. Common dielectric materials include aluminum oxide for electrolytic capacitors, ceramic materials for ceramic capacitors, and plastic films for film capacitors.

2. Conductive Materials

Conductive materials, such as aluminum or tantalum, are used for the electrodes in capacitors. The choice of conductive material affects the capacitor's performance, including its capacitance and voltage rating.

B. Sourcing and Quality Control of Raw Materials

Sourcing high-quality raw materials is essential for producing reliable filter capacitors. Manufacturers often establish relationships with trusted suppliers and implement strict quality control measures to ensure that materials meet industry standards.

IV. Design and Engineering

A. Initial Design Considerations

The design of filter capacitors involves several critical considerations:

1. Capacitance Value

The capacitance value determines how much charge a capacitor can store. Engineers must calculate the required capacitance based on the specific application.

2. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is essential to select a voltage rating that exceeds the maximum operating voltage in the circuit.

3. Temperature Stability

Temperature stability is crucial for ensuring consistent performance across varying environmental conditions. Engineers must consider the temperature coefficient of the dielectric material used.

B. Simulation and Modeling

Before moving to production, engineers often use simulation software to model the capacitor's performance under different conditions. This step helps identify potential issues and optimize the design.

C. Prototyping and Testing

Once the design is finalized, prototypes are created for testing. This phase allows engineers to evaluate the capacitor's performance and make necessary adjustments before mass production.

V. Manufacturing Process

The manufacturing process of filter capacitors involves several key steps:

A. Step 1: Preparation of Materials

The first step in the manufacturing process is the preparation of raw materials.

1. Dielectric Film Production

For film capacitors, the dielectric film is produced by extruding or casting plastic materials into thin sheets. The thickness and quality of the film are critical for the capacitor's performance.

2. Electrolyte Preparation

In the case of electrolytic capacitors, an electrolyte solution is prepared, which will be used to form the dielectric layer on the aluminum foil.

B. Step 2: Assembly

The assembly process involves layering the dielectric and conductive materials.

1. Layering of Dielectric and Conductive Materials

The dielectric material is layered between two conductive plates. For electrolytic capacitors, the aluminum foil is coated with the electrolyte to form the dielectric layer.

2. Winding or Stacking Processes

Depending on the capacitor type, the layered materials are either wound into a cylindrical shape or stacked in a rectangular configuration. This step is crucial for achieving the desired capacitance and size.

C. Step 3: Encapsulation

Encapsulation protects the capacitor from environmental factors.

1. Methods of Encapsulation

Common encapsulation methods include resin potting, plastic casing, or metal canning. The choice of encapsulation method depends on the capacitor type and its intended application.

2. Importance of Environmental Protection

Proper encapsulation ensures that the capacitor is protected from moisture, dust, and other contaminants that could affect its performance and longevity.

D. Step 4: Electrical Testing

After encapsulation, the capacitors undergo rigorous electrical testing.

1. Capacitance Measurement

Capacitance is measured to ensure it meets the specified value. This step is critical for ensuring the capacitor's performance in the circuit.

2. Leakage Current Testing

Leakage current testing checks for any unwanted current flow through the capacitor, which could indicate a failure.

3. Endurance Testing

Endurance testing simulates long-term use to ensure the capacitor can withstand the stresses of operation over time.

VI. Quality Control

A. Importance of Quality Assurance in Capacitor Production

Quality assurance is vital in capacitor production to ensure reliability and performance. Manufacturers implement strict quality control measures at every stage of the production process.

B. Testing Standards and Certifications

Capacitors must meet various industry standards and certifications, such as ISO and IEC, to ensure they are safe and reliable for use in electronic devices.

C. Continuous Improvement Processes

Manufacturers often engage in continuous improvement processes to enhance production efficiency and product quality. This may involve adopting new technologies or refining existing processes.

VII. Packaging and Distribution

A. Packaging Methods for Filter Capacitors

Proper packaging is essential to protect capacitors during transportation and storage. Common packaging methods include anti-static bags, blister packs, and bulk packaging.

B. Logistics and Distribution Channels

Efficient logistics and distribution channels are crucial for delivering capacitors to customers. Manufacturers often work with logistics partners to ensure timely and safe delivery.

C. Considerations for International Shipping

When shipping capacitors internationally, manufacturers must consider regulations, customs requirements, and potential environmental impacts.

VIII. Conclusion

In summary, the production process of filter capacitors involves several critical steps, from raw material selection to quality control and distribution. As technology advances, the demand for high-performance and sustainable capacitors continues to grow. Future trends in filter capacitor manufacturing may include the development of new materials, improved production techniques, and innovative designs that enhance performance while minimizing environmental impact. The role of innovation in this field is essential for meeting the evolving needs of the electronics industry.

IX. References

For further exploration of filter capacitors and their production processes, consider the following resources:

1. "Capacitor Technology: A Comprehensive Guide" - A detailed book on capacitor technology and applications.

2. "Electronics Components: A Guide for Engineers" - A resource for understanding various electronic components, including capacitors.

3. Industry standards from organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE).

By understanding the production process of filter capacitors, stakeholders can make informed decisions that enhance the performance and reliability of electronic devices.