What is the role of inductor core products in practical applications?

The Role of Inductor Core Products in Practical Applications

I. Introduction

Inductors are essential components in electrical circuits, serving as passive devices that store energy in a magnetic field when electrical current flows through them. Their primary function is to oppose changes in current, making them crucial for various applications, from power supplies to signal processing. Inductor core products, which include the materials and designs used to enhance the performance of inductors, play a significant role in determining the efficiency, size, and overall effectiveness of these components in practical applications. This blog post will explore the fundamental principles of inductors, the importance of core materials, their practical applications, design considerations, and future trends in inductor core products.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is defined as the property of an electrical conductor that allows it to store energy in a magnetic field. According to Faraday's Law of Electromagnetic Induction, a change in current flowing through a conductor induces a voltage across the conductor. This principle is the foundation of how inductors operate, allowing them to store energy and release it when needed.

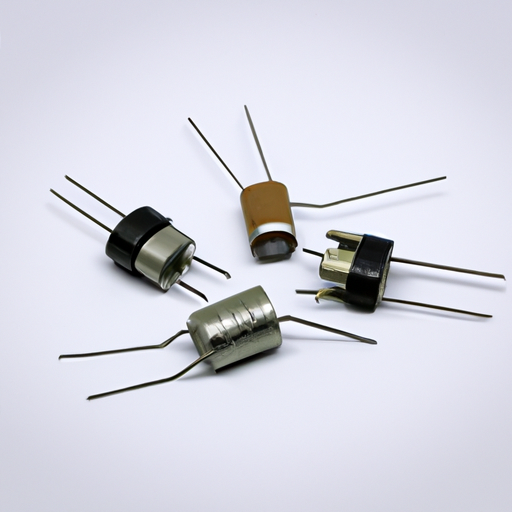

B. Components of an Inductor

An inductor typically consists of two main components: wire winding and core material. The wire winding is usually made of copper or aluminum and is coiled to create a magnetic field when current flows through it. The core material, which can be made from various substances, significantly influences the inductor's performance.

C. Types of Inductors

Inductors can be categorized into three main types:

1. **Air-core inductors**: These inductors do not use any magnetic core material, relying solely on the air surrounding the wire winding. They are typically used in high-frequency applications due to their low losses.

2. **Iron-core inductors**: These inductors use iron as the core material, which enhances the magnetic field and increases inductance. They are commonly used in power applications.

3. **Ferrite-core inductors**: Ferrite materials, which are ceramic compounds of iron oxide, are used in these inductors. They offer high magnetic permeability and low losses at high frequencies, making them suitable for various applications.

III. The Role of Core Materials in Inductors

A. Importance of Core Materials in Inductance

The core material of an inductor is crucial for its performance. The magnetic permeability of the core material determines how effectively the inductor can store energy. Additionally, the saturation magnetization of the core material affects the maximum amount of magnetic flux it can handle before becoming ineffective.

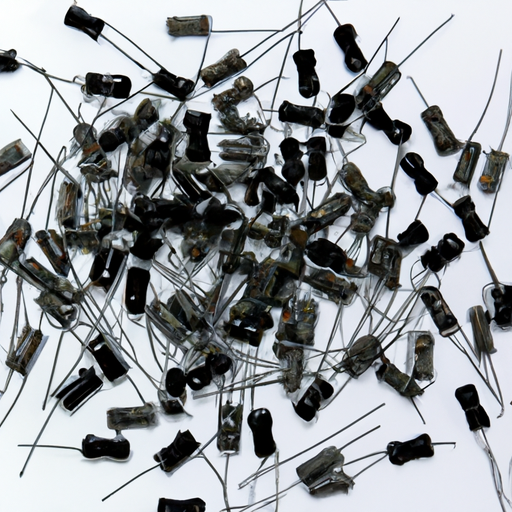

B. Common Core Materials

Several core materials are commonly used in inductors:

1. **Ferrite**: Ferrite cores are popular due to their high magnetic permeability and low eddy current losses, making them ideal for high-frequency applications.

2. **Iron powder**: Iron powder cores are used in applications requiring high inductance and low cost. They are often found in power inductors.

3. **Laminated steel**: Laminated steel cores are used in transformers and inductors where high power handling is required. The laminations reduce eddy current losses, improving efficiency.

C. Impact of Core Material on Performance

The choice of core material significantly impacts an inductor's performance. Factors such as efficiency, size, weight, and frequency response are all influenced by the core material. For instance, ferrite cores are lightweight and compact, making them suitable for portable devices, while iron powder cores may be bulkier but offer higher inductance.

IV. Practical Applications of Inductor Core Products

Inductor core products find applications across various fields, including:

A. Power Electronics

Inductors are integral to power electronics, where they are used in:

1. **Switching power supplies**: Inductors help regulate voltage and current, ensuring stable power delivery.

2. **DC-DC converters**: Inductors store energy during the conversion process, improving efficiency.

3. **Inverters**: Inductors are used to convert DC to AC power, essential for renewable energy systems.

B. Signal Processing

In signal processing, inductors are used in:

1. **Filters**: Inductors are key components in low-pass, high-pass, and band-pass filters, allowing specific frequency ranges to pass while blocking others.

2. **RF applications**: Inductors are used in radio frequency circuits to tune and filter signals.

C. Energy Storage

Inductive energy storage systems utilize inductors to store energy for later use. This technology is particularly relevant in renewable energy systems, where inductors help manage energy flow from sources like solar panels and wind turbines.

D. Automotive Applications

In the automotive industry, inductors play a vital role in:

1. **Electric vehicles**: Inductors are used in power management systems to optimize energy use and improve efficiency.

2. **Power management systems**: Inductors help regulate power distribution in various automotive applications, ensuring reliable operation.

E. Telecommunications

Inductors are essential in telecommunications for:

1. **Signal conditioning**: Inductors help improve signal quality by filtering out noise.

2. **Impedance matching**: Inductors are used to match the impedance of different components, ensuring efficient signal transmission.

V. Design Considerations for Inductor Core Products

When designing inductor core products, several considerations must be taken into account:

A. Selecting the Right Core Material

Choosing the appropriate core material is critical and depends on application requirements and cost considerations. For instance, ferrite cores may be preferred for high-frequency applications, while iron powder cores may be more cost-effective for power applications.

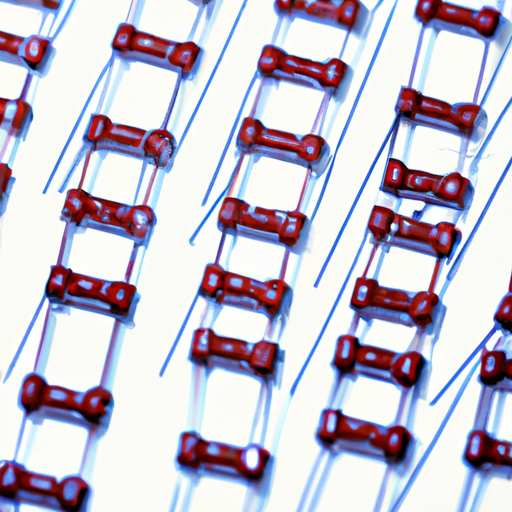

B. Core Geometry and Winding Techniques

The geometry of the core and the winding techniques used can significantly influence inductance and efficiency. Designers must consider trade-offs, such as the balance between size and performance.

C. Thermal Management

Inductors generate heat during operation, making thermal management essential. Effective cooling techniques, such as heat sinks or airflow management, can help maintain optimal operating temperatures and prevent performance degradation.

VI. Future Trends in Inductor Core Products

The field of inductor core products is evolving, with several trends shaping its future:

A. Advances in Core Materials

Innovations in core materials, such as nanocrystalline and composite materials, are enhancing the performance of inductors. These materials offer improved magnetic properties and reduced losses, making them suitable for high-efficiency applications.

B. Miniaturization and Integration

As technology advances, there is a growing trend toward miniaturization and integration of inductors with other components. Compact designs are becoming increasingly important in portable devices, where space is limited.

C. Sustainability and Environmental Considerations

Sustainability is becoming a key focus in the manufacturing of inductor core products. Efforts to recycle core materials and develop eco-friendly manufacturing processes are gaining traction, aligning with global sustainability goals.

VII. Conclusion

Inductor core products play a vital role in various practical applications, from power electronics to telecommunications. Understanding the principles of inductance, the importance of core materials, and the design considerations involved is essential for optimizing inductor performance. As technology continues to evolve, the role of inductors will expand, driven by advances in materials, miniaturization, and sustainability. The future of inductor core products promises exciting developments that will enhance their effectiveness and broaden their applications in modern technology.

VIII. References

1. Academic papers and articles on inductors and their applications.

2. Industry reports on trends in power electronics and signal processing.

3. Books on electrical engineering and the principles of inductance.

This comprehensive exploration of inductor core products highlights their significance in practical applications and sets the stage for future innovations in the field.