What kind of product is an inductor manufacturer?

What Kind of Product is an Inductor Manufacturer?

I. Introduction

Inductors are fundamental components in the realm of electronics, playing a crucial role in the functioning of various circuits. Defined as passive electrical components that store energy in a magnetic field when electrical current flows through them, inductors are essential for managing current and voltage in electronic devices. Their importance cannot be overstated, as they are integral to power supplies, filters, transformers, and radio frequency (RF) applications. This blog post will explore the world of inductor manufacturers, shedding light on their products, processes, and the challenges they face in a rapidly evolving market.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes a change in current. When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This principle is governed by Faraday's law of electromagnetic induction, which states that a change in magnetic flux through a circuit induces an electromotive force (EMF) in that circuit.

B. Types of Inductors

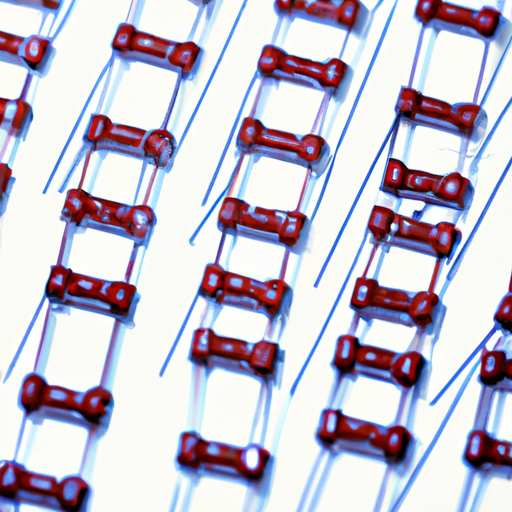

Inductors come in various types, each designed for specific applications and performance characteristics:

1. **Air Core Inductors**: These inductors use air as the core material, making them lightweight and suitable for high-frequency applications. They are often used in RF circuits.

2. **Iron Core Inductors**: Featuring an iron core, these inductors provide higher inductance values and are commonly used in power applications due to their ability to handle larger currents.

3. **Ferrite Core Inductors**: Ferrite cores are made from a ceramic material that is magnetically conductive. These inductors are ideal for high-frequency applications and are often used in switch-mode power supplies.

4. **Toroidal Inductors**: Shaped like a doughnut, toroidal inductors have a closed magnetic path, which minimizes electromagnetic interference and enhances efficiency. They are widely used in audio equipment and power supplies.

5. **Variable Inductors**: These inductors allow for adjustable inductance values, making them useful in tuning circuits and applications where flexibility is required.

C. Applications of Inductors

Inductors find applications across a wide range of electronic devices:

1. **Power Supplies**: Inductors are crucial in switching power supplies, where they help regulate voltage and current.

2. **Filters**: In audio and RF applications, inductors are used in filters to block unwanted frequencies while allowing desired signals to pass.

3. **Transformers**: Inductors are integral components of transformers, which transfer electrical energy between circuits through electromagnetic induction.

4. **RF Applications**: In radio frequency circuits, inductors are used for tuning and impedance matching, ensuring optimal signal transmission.

III. The Role of Inductor Manufacturers

A. Overview of the Manufacturing Process

The manufacturing of inductors involves several key steps:

1. **Material Selection**: The choice of materials is critical in determining the performance characteristics of the inductor. Manufacturers must select appropriate wire, core materials, and insulation based on the intended application.

2. **Design and Engineering**: Engineers design inductors to meet specific electrical and physical requirements. This phase includes simulations and modeling to optimize performance.

3. **Production Techniques**: Various production techniques, such as winding, soldering, and encapsulation, are employed to create inductors. Automation is increasingly used to enhance efficiency and precision.

B. Quality Control and Testing

Quality control is paramount in inductor manufacturing. Manufacturers implement rigorous testing methods to ensure that inductors meet industry standards and customer specifications. Common testing methods include:

1. **Inductance Measurement**: This involves measuring the inductance value to ensure it falls within specified tolerances.

2. **DC Resistance Testing**: Measuring the resistance of the inductor helps assess its efficiency and performance.

3. **Thermal Testing**: Inductors are tested under various temperature conditions to evaluate their performance and reliability.

C. Custom Inductor Manufacturing

Many manufacturers offer custom inductor solutions tailored to specific applications. This involves close collaboration with clients to understand their requirements and develop inductors that meet their unique needs. Custom manufacturing can include variations in size, inductance value, and core material.

IV. Market Trends and Innovations

A. Current Trends in the Inductor Market

The inductor market is witnessing several trends that reflect the evolving needs of the electronics industry:

1. **Miniaturization of Components**: As electronic devices become smaller and more compact, there is a growing demand for miniaturized inductors that can fit into tight spaces without compromising performance.

2. **Increased Demand for High-Frequency Inductors**: With the rise of wireless communication and high-speed data transfer, there is a significant demand for inductors that can operate efficiently at high frequencies.

B. Technological Advancements

Technological advancements are driving innovation in inductor manufacturing:

1. **New Materials and Designs**: Manufacturers are exploring new materials, such as composite cores, to enhance performance and reduce losses.

2. **Automation in Manufacturing Processes**: Automation is streamlining production processes, improving efficiency, and reducing costs.

C. Environmental Considerations

Sustainability is becoming increasingly important in the manufacturing sector:

1. **Sustainable Manufacturing Practices**: Many manufacturers are adopting eco-friendly practices, such as reducing waste and energy consumption during production.

2. **Recycling and End-of-Life Management**: Manufacturers are also focusing on recycling materials and managing the end-of-life of inductors to minimize environmental impact.

V. Challenges Faced by Inductor Manufacturers

Despite the opportunities in the inductor market, manufacturers face several challenges:

A. Competition in the Global Market

The inductor manufacturing industry is highly competitive, with numerous players vying for market share. Manufacturers must continuously innovate and improve their products to stay ahead.

B. Supply Chain Issues

Global supply chain disruptions can impact the availability of raw materials and components, leading to delays in production and increased costs.

C. Meeting Evolving Customer Demands

As technology advances, customer demands are constantly changing. Manufacturers must be agile and responsive to these evolving needs to remain relevant.

D. Regulatory Compliance and Standards

Inductor manufacturers must adhere to various industry standards and regulations, which can vary by region. Ensuring compliance can be a complex and resource-intensive process.

VI. Conclusion

Inductor manufacturers play a vital role in the electronics industry, providing essential components that enable the functionality of countless devices. From understanding the basic principles of inductance to navigating market trends and challenges, the journey of an inductor manufacturer is both complex and rewarding. As technology continues to evolve, the future outlook for the inductor industry remains promising, with opportunities for innovation and growth. Ultimately, inductors will continue to be a cornerstone of technological advancement, driving innovation in various fields.

VII. References

1. Academic journals and articles on inductors and their applications.

2. Industry reports on market trends and forecasts for inductors.

3. Manufacturer websites and product catalogs for specific inductor products and specifications.

This comprehensive overview highlights the significance of inductor manufacturers and their contributions to the ever-evolving landscape of technology.