What are the advantages of magnetic bead inductor products?

What are the Advantages of Magnetic Bead Inductor Products?

I. Introduction

In the realm of electronics, inductors play a crucial role in managing electrical energy. Among the various types of inductors, magnetic bead inductors have gained significant attention due to their unique properties and advantages. This article aims to explore the benefits of magnetic bead inductor products, shedding light on their structure, performance, and applications in modern electronic circuits.

II. Overview of Magnetic Bead Inductors

A. Structure and Composition

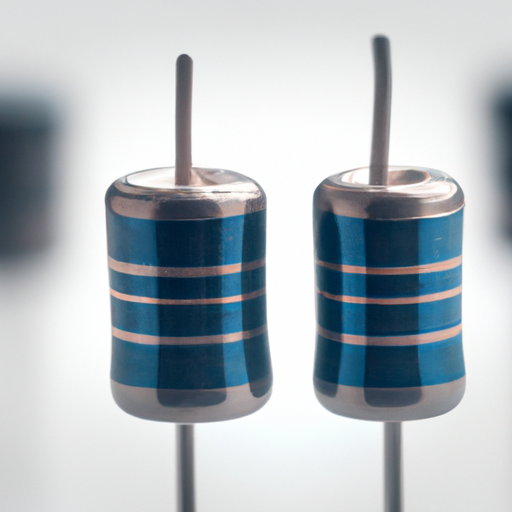

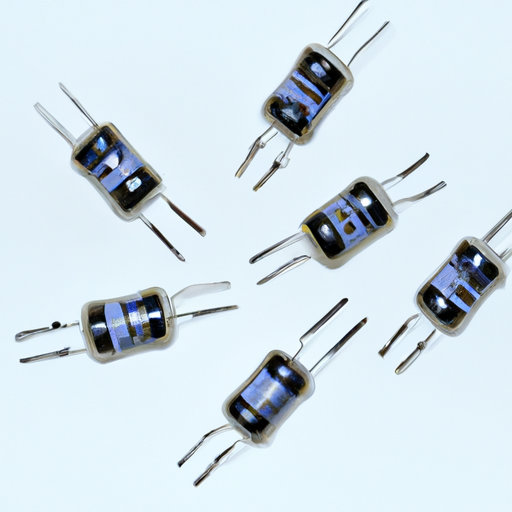

Magnetic bead inductors are compact passive components that consist of a magnetic core surrounded by a wire coil. The core is typically made from ferrite materials, which enhance the inductor's performance by providing a medium for magnetic flux. The design features of magnetic bead inductors include their small size and the ability to handle high frequencies, making them ideal for various applications.

B. Types of Magnetic Bead Inductors

There are several variants of magnetic bead inductors, each tailored for specific applications. Common types include surface mount inductors, through-hole inductors, and integrated inductors. These components find applications across various industries, including telecommunications, consumer electronics, automotive, and industrial automation.

III. Key Advantages of Magnetic Bead Inductor Products

A. High Inductance Values

Inductance is a measure of an inductor's ability to store energy in a magnetic field. Magnetic bead inductors are known for their high inductance values, which are beneficial in circuit design. High inductance allows for better energy storage and smoother current flow, making them essential in power supply circuits and filtering applications.

B. Compact Size and Lightweight

One of the standout features of magnetic bead inductors is their compact size and lightweight nature. This space-saving benefit is crucial in modern electronics, where miniaturization is a key trend. The reduced footprint of these inductors allows for more efficient use of space on printed circuit boards (PCBs), contributing to the overall portability of electronic devices.

C. Enhanced Performance

Magnetic bead inductors exhibit low direct current (DC) resistance, which translates to reduced power loss during operation. Additionally, they possess a high current handling capability, making them suitable for applications that require efficient energy transfer. This enhanced performance is vital in power management systems, where efficiency is paramount.

D. Improved Signal Integrity

In electronic circuits, electromagnetic interference (EMI) can significantly degrade signal quality. Magnetic bead inductors help mitigate this issue by reducing EMI and providing better noise filtering. This improvement in signal integrity is particularly important in high-frequency applications, such as RF and communication devices, where clear signal transmission is essential.

E. Versatility in Applications

The versatility of magnetic bead inductors is another significant advantage. They are widely used in power supply circuits, where they help regulate voltage and current. Additionally, their applications extend to RF and communication devices, where they play a crucial role in signal processing and filtering. This adaptability makes them a preferred choice for engineers and designers across various sectors.

F. Cost-Effectiveness

When compared to other types of inductors, magnetic bead inductors offer a cost-effective solution without compromising performance. Their efficient design and manufacturing processes contribute to lower production costs, making them an attractive option for businesses looking to optimize their budgets. Furthermore, the long-term economic benefits of using magnetic bead inductors, such as reduced energy consumption and improved reliability, enhance their overall value.

IV. Technical Advantages

A. Thermal Stability

Magnetic bead inductors are designed to perform reliably under high temperatures, making them suitable for harsh environments. Their thermal stability ensures that they maintain consistent performance even in challenging conditions, which is crucial for applications in automotive and industrial sectors.

B. Frequency Response

These inductors exhibit excellent performance across a wide range of frequencies. Their ability to handle high-frequency signals makes them ideal for applications in telecommunications and RF systems. This frequency response ensures that magnetic bead inductors can meet the demands of modern electronic devices that operate at varying frequencies.

C. Customization Options

Manufacturers of magnetic bead inductors often provide customization options to meet specific design requirements. This flexibility allows engineers to tailor inductors to their unique needs, whether it be in terms of inductance value, size, or other specifications. Additionally, standardized products are readily available, making it easy for designers to find suitable components for their projects.

V. Challenges and Considerations

A. Limitations of Magnetic Bead Inductors

Despite their numerous advantages, magnetic bead inductors do have limitations. One significant challenge is their saturation current limitations, which can restrict their performance in high-current applications. Additionally, frequency limitations may arise in certain designs, necessitating careful consideration during the selection process.

B. Selection Criteria for Designers

When choosing magnetic bead inductors, designers must consider several key factors. These include the required inductance value, current rating, size constraints, and cost considerations. Balancing performance and cost is essential to ensure that the selected inductor meets the specific needs of the application while remaining economically viable.

VI. Future Trends in Magnetic Bead Inductor Technology

A. Innovations in Materials and Design

As technology continues to evolve, so too does the field of magnetic bead inductors. Innovations in materials and design are paving the way for even more efficient and effective inductors. Research into advanced magnetic materials and manufacturing techniques is expected to enhance the performance and reliability of these components.

B. Growing Demand in Emerging Technologies

The demand for magnetic bead inductors is on the rise, particularly in emerging technologies such as the Internet of Things (IoT) and electric vehicles (EVs). As these sectors expand, the need for efficient power management and signal integrity will drive further innovation in magnetic bead inductor technology.

C. Sustainability and Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on sustainability in their production processes. This includes the use of eco-friendly materials and practices that minimize waste. As a result, magnetic bead inductors are likely to become more sustainable, aligning with global efforts to reduce the environmental impact of electronic components.

VII. Conclusion

In summary, magnetic bead inductors offer a multitude of advantages that make them indispensable in modern electronics. Their high inductance values, compact size, enhanced performance, and versatility in applications position them as a preferred choice for engineers and designers. As technology continues to advance, the importance of magnetic bead inductors will only grow, paving the way for innovative solutions in various industries. The future of magnetic bead inductor technology looks promising, with ongoing developments in materials, design, and sustainability that will further enhance their role in electronic circuits.

VIII. References

1. "Inductor Basics: Understanding Inductance and Its Applications." Electronics Tutorials.

2. "The Role of Inductors in Power Supply Design." IEEE Xplore.

3. "Emerging Trends in Inductor Technology." Journal of Electronic Materials.

4. "Magnetic Bead Inductors: A Comprehensive Guide." Digi-Key Electronics.

5. "Sustainability in Electronics Manufacturing." Environmental Science & Technology.

This blog post provides a thorough exploration of the advantages of magnetic bead inductor products, highlighting their significance in modern electronic applications and their potential for future development.