What product types do standard capacitors include?

What Product Types Do Standard Capacitors Include?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are passive electrical devices that store electrical energy in an electric field, allowing them to release that energy when needed. This article aims to provide a comprehensive overview of the various types of standard capacitors, their construction, applications, advantages, and limitations. Understanding these product types is essential for engineers, hobbyists, and anyone interested in electronics.

II. Basic Concepts of Capacitors

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store an electric charge. It is measured in farads (F), with common subunits being microfarads (µF) and picofarads (pF). The capacitance value indicates how much charge a capacitor can hold at a given voltage. The relationship between charge (Q), capacitance (C), and voltage (V) is given by the formula:

\[ Q = C \times V \]

B. How Capacitors Store and Release Energy

Capacitors store energy in the form of an electric field created between two conductive plates separated by an insulating material (dielectric). When a voltage is applied across the plates, an electric field develops, allowing the capacitor to store energy. When the voltage is removed or reduced, the capacitor can release this stored energy back into the circuit.

C. Key Parameters: Voltage Rating, Capacitance Value, and Tolerance

When selecting a capacitor, three key parameters must be considered:

1. **Voltage Rating**: The maximum voltage a capacitor can handle without breaking down.

2. **Capacitance Value**: The amount of charge the capacitor can store, which affects its performance in a circuit.

3. **Tolerance**: The allowable deviation from the stated capacitance value, which can impact circuit functionality.

III. Types of Standard Capacitors

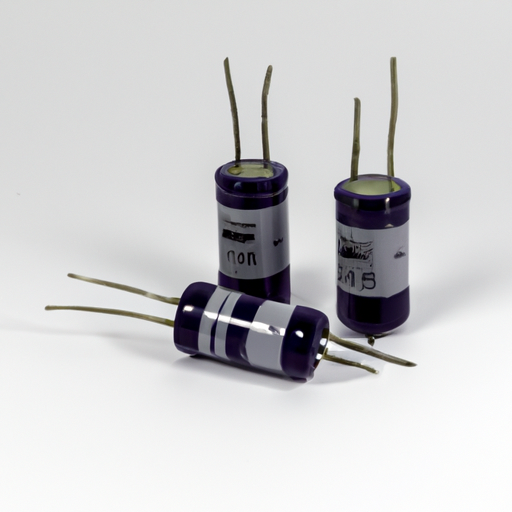

A. Electrolytic Capacitors

1. Description and Construction

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They typically have a high capacitance value and are constructed with aluminum or tantalum oxide.

2. Applications and Advantages

Electrolytic capacitors are widely used in power supply circuits, audio equipment, and signal coupling applications due to their high capacitance and relatively low cost.

3. Limitations and Disadvantages

The main limitations of electrolytic capacitors include their polarity (they must be connected correctly in a circuit), limited lifespan, and susceptibility to leakage current.

B. Ceramic Capacitors

1. Description and Construction

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are available in various capacitance values and voltage ratings.

2. Applications and Advantages

These capacitors are commonly used in high-frequency applications, decoupling, and filtering due to their stability and low equivalent series resistance (ESR).

3. Limitations and Disadvantages

Ceramic capacitors can exhibit capacitance changes with temperature and voltage, which may not be suitable for all applications.

C. Film Capacitors

1. Description and Construction

Film capacitors use a thin plastic film as the dielectric material. They are available in various types, including polyester, polypropylene, and polycarbonate.

2. Applications and Advantages

Film capacitors are known for their stability, low loss, and high insulation resistance, making them ideal for audio applications, timing circuits, and power electronics.

3. Limitations and Disadvantages

While film capacitors are reliable, they tend to be larger and more expensive than other types, which may limit their use in compact designs.

D. Tantalum Capacitors

1. Description and Construction

Tantalum capacitors are similar to electrolytic capacitors but use tantalum as the anode material. They are known for their high capacitance in a small package.

2. Applications and Advantages

These capacitors are often used in applications requiring stable capacitance and low leakage current, such as in mobile devices and military equipment.

3. Limitations and Disadvantages

Tantalum capacitors can be sensitive to voltage spikes and may fail catastrophically if subjected to overvoltage conditions.

E. Mica Capacitors

1. Description and Construction

Mica capacitors use natural mica as the dielectric material. They are known for their excellent stability and low loss.

2. Applications and Advantages

Mica capacitors are often used in RF applications, oscillators, and precision timing circuits due to their high accuracy and reliability.

3. Limitations and Disadvantages

The main drawbacks of mica capacitors are their higher cost and larger size compared to other types.

F. Supercapacitors (Ultracapacitors)

1. Description and Construction

Supercapacitors, also known as ultracapacitors, have a much higher capacitance than traditional capacitors and can store large amounts of energy. They use a combination of electrostatic and electrochemical processes.

2. Applications and Advantages

Supercapacitors are used in applications requiring rapid charge and discharge cycles, such as energy storage systems, regenerative braking in electric vehicles, and backup power supplies.

3. Limitations and Disadvantages

Despite their advantages, supercapacitors have lower energy density compared to batteries, which limits their use in long-term energy storage applications.

IV. Specialized Capacitors

A. Variable Capacitors

1. Description and Construction

Variable capacitors allow for adjustable capacitance values, typically achieved through mechanical movement of the plates.

2. Applications and Advantages

They are commonly used in tuning circuits, such as radios, where precise capacitance adjustments are necessary.

B. Non-Polarized Capacitors

1. Description and Construction

Non-polarized capacitors can be connected in either direction in a circuit, making them versatile for various applications.

2. Applications and Advantages

These capacitors are often used in AC applications, such as motor run capacitors and coupling applications.

C. Power Capacitors

1. Description and Construction

Power capacitors are designed to handle high voltage and current levels, often used in power factor correction and energy storage applications.

2. Applications and Advantages

They are essential in industrial applications, helping to improve the efficiency of electrical systems.

V. Factors Influencing Capacitor Selection

A. Application Requirements

The specific needs of the application, such as capacitance value, voltage rating, and frequency response, will dictate the type of capacitor to use.

B. Environmental Considerations

Factors such as temperature, humidity, and potential exposure to chemicals can affect capacitor performance and lifespan.

C. Cost and Availability

Budget constraints and the availability of specific capacitor types can also influence the selection process.

VI. Conclusion

Understanding the various types of standard capacitors is essential for anyone involved in electronics. Each type has its unique characteristics, advantages, and limitations, making them suitable for different applications. As technology advances, new capacitor technologies are emerging, promising improved performance and efficiency. For those interested in delving deeper into the world of capacitors, further exploration and learning are encouraged.

VII. References

For further information on capacitors and their applications, consider the following resources:

1. "Capacitors: Principles and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online resources such as educational websites and electronics forums.