What are the product features of capacitor grounding?

What are the Product Features of Capacitor Grounding?

I. Introduction

Capacitor grounding is a critical aspect of electrical engineering that ensures the safety, stability, and efficiency of electrical systems. By connecting capacitors to the ground, engineers can mitigate risks associated with electrical faults, enhance system performance, and improve overall reliability. This article aims to explore the product features of capacitor grounding, highlighting its importance in various applications and the benefits it brings to electrical systems.

II. Understanding Capacitor Grounding

A. Explanation of Capacitors and Their Role in Electrical Systems

Capacitors are passive electrical components that store and release electrical energy. They play a vital role in various applications, including power factor correction, energy storage, and filtering. In electrical systems, capacitors help manage voltage levels, reduce reactive power, and improve overall system efficiency.

B. The Concept of Grounding in Electrical Engineering

Grounding refers to the process of connecting electrical systems to the earth or a conductive body that serves as a reference point for voltage. This connection is crucial for safety, as it provides a path for fault currents to flow safely to the ground, preventing electrical shock hazards and equipment damage.

C. The Relationship Between Capacitors and Grounding

Capacitor grounding combines the benefits of capacitors with the safety and stability provided by grounding. By grounding capacitors, engineers can enhance the performance of electrical systems while ensuring that any faults are safely managed.

III. Key Features of Capacitor Grounding

A. Safety Enhancements

1. **Protection Against Electrical Faults**: Grounding capacitors helps protect electrical systems from faults such as short circuits and overloads. By providing a low-resistance path to the ground, fault currents can be safely diverted, minimizing the risk of damage to equipment.

2. **Reduction of Shock Hazards**: Grounding reduces the risk of electrical shock to personnel working on or near electrical systems. In the event of a fault, the grounded capacitor ensures that any stray voltage is directed away from individuals, enhancing workplace safety.

3. **Prevention of Equipment Damage**: By mitigating the effects of electrical faults, capacitor grounding helps prevent damage to sensitive equipment. This protection is particularly important in industrial and commercial settings where downtime can result in significant financial losses.

B. Improved System Stability

1. **Voltage Regulation**: Grounded capacitors help maintain stable voltage levels within electrical systems. By providing reactive power support, they can counteract voltage fluctuations caused by varying loads, ensuring consistent performance.

2. **Reduction of Harmonic Distortion**: Capacitor grounding can help reduce harmonic distortion in electrical systems, which can lead to inefficiencies and equipment malfunctions. By filtering out unwanted harmonics, grounded capacitors contribute to cleaner power quality.

3. **Enhanced Power Factor Correction**: Grounded capacitors improve the power factor of electrical systems by compensating for reactive power. A better power factor leads to reduced energy costs and improved system efficiency.

C. Enhanced Performance

1. **Increased Efficiency of Electrical Systems**: By optimizing voltage levels and reducing losses, capacitor grounding enhances the overall efficiency of electrical systems. This efficiency translates to lower energy consumption and reduced operational costs.

2. **Improved Response Times in Power Systems**: Grounded capacitors can respond quickly to changes in load conditions, ensuring that electrical systems can adapt to varying demands without compromising performance.

3. **Better Load Balancing**: Capacitor grounding helps distribute loads more evenly across electrical systems, reducing the risk of overloading specific components and enhancing overall system reliability.

D. Maintenance and Monitoring

1. **Ease of Installation and Maintenance**: Grounding capacitors can be easily integrated into existing electrical systems, making installation straightforward. Additionally, regular maintenance is simplified due to the clear grounding connections.

2. **Integration with Monitoring Systems**: Many modern capacitor grounding systems can be integrated with monitoring technologies, allowing for real-time assessment of system performance and health.

3. **Diagnostic Capabilities for Early Fault Detection**: Grounded capacitor systems can provide diagnostic information that helps identify potential issues before they escalate into serious problems, enabling proactive maintenance.

IV. Types of Capacitor Grounding Systems

A. Grounded Capacitor Banks

1. **Description and Applications**: Grounded capacitor banks consist of multiple capacitors connected to the ground. They are commonly used in industrial and commercial applications to improve power factor and voltage stability.

2. **Advantages and Disadvantages**: The primary advantage of grounded capacitor banks is their ability to provide reliable voltage support. However, they may require more complex installation and maintenance compared to ungrounded systems.

B. Ungrounded Capacitor Systems

1. **Description and Applications**: Ungrounded capacitor systems do not have a direct connection to the ground. They are often used in specific applications where grounding may not be feasible.

2. **Advantages and Disadvantages**: While ungrounded systems can offer flexibility, they may pose higher risks in terms of safety and fault management, making them less suitable for many applications.

C. Grounding Techniques

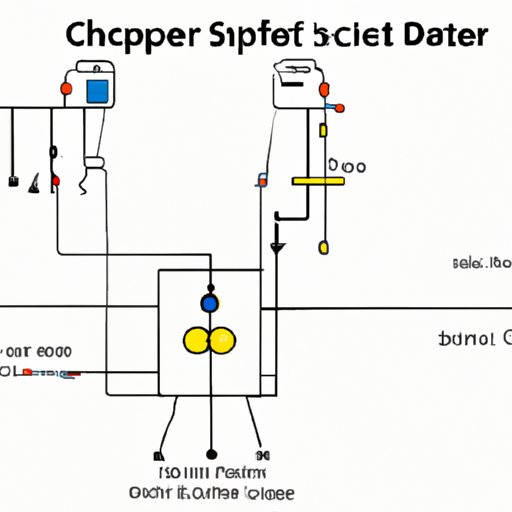

1. **Solid Grounding**: This technique involves directly connecting the capacitor to the ground, providing a low-resistance path for fault currents.

2. **Resistance Grounding**: In this method, a resistor is placed in the grounding path to limit fault currents, providing a balance between safety and system performance.

3. **Reactance Grounding**: This technique uses inductive reactance to limit fault currents while still providing grounding benefits, making it suitable for specific applications.

V. Applications of Capacitor Grounding

A. Industrial Applications

1. **Manufacturing Facilities**: Capacitor grounding is essential in manufacturing environments where large motors and machinery operate. It helps maintain voltage stability and protects equipment from faults.

2. **Power Generation Plants**: In power generation, capacitor grounding ensures reliable operation and enhances the efficiency of power distribution systems.

B. Commercial Applications

1. **Office Buildings**: Capacitor grounding in office buildings helps maintain power quality and reduces energy costs, contributing to a more efficient work environment.

2. **Retail Environments**: Retail spaces benefit from capacitor grounding by ensuring that lighting and other electrical systems operate reliably, enhancing the customer experience.

C. Renewable Energy Systems

1. **Wind and Solar Power Installations**: Capacitor grounding is crucial in renewable energy systems, where it helps manage voltage fluctuations and improve overall system performance.

2. **Energy Storage Systems**: In energy storage applications, capacitor grounding enhances the reliability and efficiency of battery systems, ensuring optimal performance.

VI. Challenges and Considerations

A. Potential Issues with Capacitor Grounding

1. **Overvoltage Conditions**: Improper grounding can lead to overvoltage conditions, which may damage equipment and pose safety risks.

2. **Ground Fault Currents**: Ground faults can create hazardous conditions if not properly managed, making effective grounding essential.

3. **System Complexity**: The integration of capacitor grounding can add complexity to electrical systems, requiring careful design and planning.

B. Best Practices for Effective Capacitor Grounding

1. **Regular Maintenance and Inspections**: Routine checks and maintenance are crucial to ensure the integrity of grounding systems and prevent potential issues.

2. **Proper System Design and Configuration**: Careful planning and design are essential to optimize the benefits of capacitor grounding while minimizing risks.

3. **Compliance with Industry Standards**: Adhering to industry standards and guidelines ensures that capacitor grounding systems are safe and effective.

VII. Conclusion

Capacitor grounding is a vital component of modern electrical systems, providing numerous benefits in terms of safety, stability, and performance. By understanding the key features and applications of capacitor grounding, engineers and facility managers can make informed decisions that enhance the reliability and efficiency of their electrical systems. As technology continues to evolve, the importance of effective capacitor grounding will only grow, paving the way for safer and more efficient electrical infrastructure.

VIII. References

A. Suggested readings and resources for further exploration

B. Industry standards and guidelines related to capacitor grounding

---

This blog post provides a comprehensive overview of the product features of capacitor grounding, emphasizing its significance in various applications and the benefits it offers to electrical systems. By understanding these features, stakeholders can make informed decisions that enhance safety, stability, and performance in their electrical infrastructure.